Patented multi-cavity technology to achieve differential crushing effect

Font: Large Small Date:2017/12/12

With the modernization and scale development of industries including feed, protein feed, alcohol, biomass, enterprises’ requirements for raw material processing equipment have become more and more strict, even formulate a series of harsh standard to the key performance indicators of hammer mill, especially on crushing efficiency, crushing effect and stability, which can create value for customers and bring more economic benefits.

High efficiency crushing production line, to create differential competitive advantage for customers

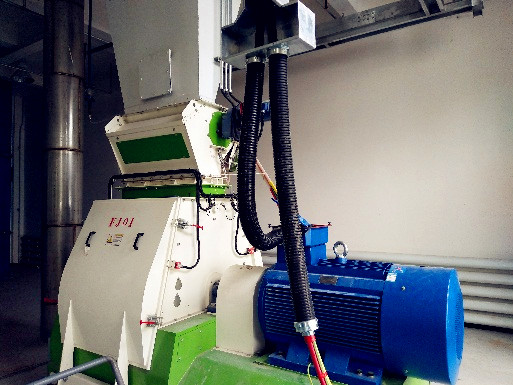

The corn crushing project uses ZHENG CHANG champion hammer mill, patented multi-cavity technology with crushing efficiency increased by 30%.

SFSP138×75F champion hammer mill

Leading production capacity with the same power consumption in China by using advanced multi-cavity technology to solve material stacking problem. Different kinds of professional hammer mill specialized in crushing shrimp, animal protein, alcohol tank, cassava, pasture, sawdust, biomass energy, etc.

High output, low energy consumption

The upgraded F series hammer mill, production output is improved by 30%, higher than the domestic same power type.

The multi-cavity design makes the wear of the hammer and screen mesh more uniform and improves the service life of wearing parts.

The feeder can remove the impurities such as stone and metal in the raw material, to improve the quality of feed and prolong the service life of equipment.

The feeding volume can be adjusted automatically to ensure the full load operation of hammer mill and to improve the efficiency.

The system can be equipped with rotating shaft and temperature detection system, to realize automatic warning alarm and shutdown with fault.